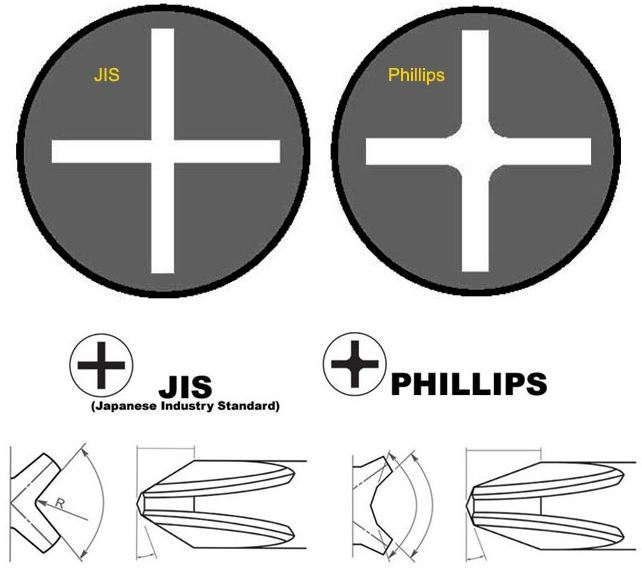

Ok so another issue I ran into and this is not a new one, been here before. As I was working on splitting the case the tiresome issue of phillips head screws caused me some heartburn. I have a hand impact driver but as usual the phillips bits I had for it didn't fit the screw heads well enough to break them loose without rounding off. I have a large craftsman phillips screwdriver that does fit the screw heads good and I did manage to break all the screws loose by hammer tapping while turning.

I will need to replace all of these screws for reassembly, and recall reading in other rebuild post where they replaced them with hex head Allen screws.

Can one of you guys give me some info on getting the right size screws to replace them? I know they sell the replacement screw kits, but there's only a couple sizes needed and I'll need quite a few of them.